Failure Analysis

Signs of Unusual Wear

(DISCLAIMER: Before beginning, please note that not all brake complaints and problems can be solved by only brake shoe inspection. Common problems also occur as a result of high temperature issues, such as air, mechanical or friction imbalances. Any imbalance in one or a combination of all three will appear as a friction material issue. The necessity for inspecting and replacing all worn parts has become more critical with the advent of automatic slack adjusters and ABS.)

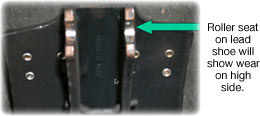

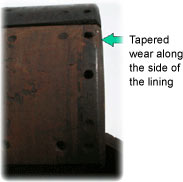

When brake drums are removed, the brake lining should be inspected for signs of unusual or atypical wear. Common problems may arise as a result of ignoring hardware upkeep and s-cam bushings. These problems include but are not limited to: Bottom brake shoe worn more than the top shoe; Lead shoe blocks primary contact, with very little contact on the anchor block; Excessively noisy brakes.